How Procurement delays hold up project completion

In this post, I will attempt to throw light on the Procurement Phase in EPC Projects, specifically, the challenges and limitations that can affect this phase and potentially delay project completion.

Procurement carries more than 50% of the weightage in EPC projects, with 90% of the cash flow depending on the timely delivery of materials and their related activities. Over the years I have rarely seen a project schedule that didn’t have the delivery of at least one item in the critical path. In fact, material deliveries influence the cash flow, schedule completion and profit margin of every single project.

How do companies manage this critical activity of procurement?

I have seen that ERP systems are widely used to track the sourcing of materials with focus on the commercial aspect of the sourcing process. So how is the technical side of the procurement activities being tracked? How complex and critical is this ‘other side’ of the process? Let’s delve into that a bit.

Many stakeholders, multiple Documents, different phase gates and one PO.

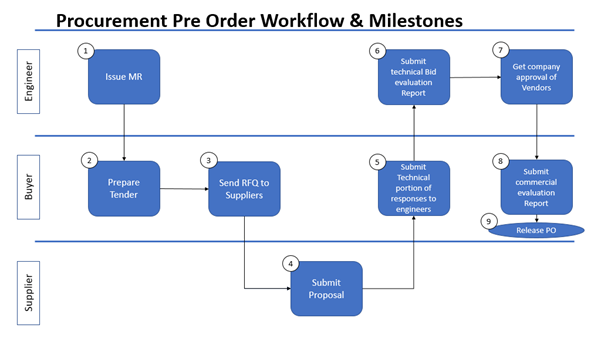

Prior to the release of one purchase order there are at least nine stages (apart from the vendor registration process) and at each of these stages multiple stake holders have to review, comment and approve different documents before the next stage can be initiated. All these stages are done through e-mail transfer or through manual mode. The importance of tracking the progress at each stage against the set schedule cannot be overstated, considering the criticality of placing the purchase orders.

Security Restrictions

An important requirement of the Procurement Process is data privacy. With multiple users, you need to have appropriate security settings so that only the document intended for that particular person’s view can be accessed through the system. This is important because of the competitive bidding and the sensitivity around Project budgets, and to foster unbiased decision-making.

Importance of Procurement Documents

Procurement activities are subject to multiple audits due to the complexity of the process and its commercial impact on the project. Hence, the upkeep of procurement documentation is very important to project management teams. Procurement-related documents need to be archived in a structured manner for accessing by auditors and as reference for future projects. Also, the material requisitions, vendor offers etc. need to be made accessible to the stakeholders for closing out the POs and to negotiate any change orders, or for applying liquidate damages if needed. Managing these procurement documents through e-mail or other file sharing methods do not guarantee the accuracy and availability of documents.

So the above are a few of the inherent challenges of the procurement process.

Further, we can divide procurement into two major phases - Pre-order and Post-order. In this post I will discuss the importance and complexity of the pre-order phase, and lay out a few workable solutions to automate the process.

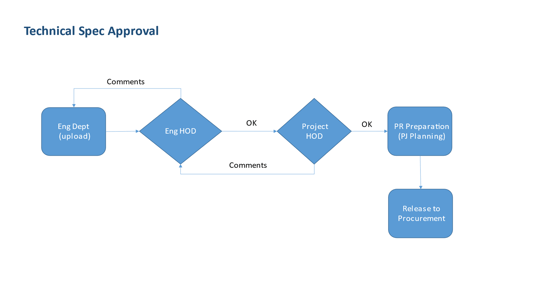

The process starts when the procurement team receives an approved Material Requisition with a required-at-site date. The buyer has to initiate the request for Quotation based on the approved material request received from the Engineering teams.

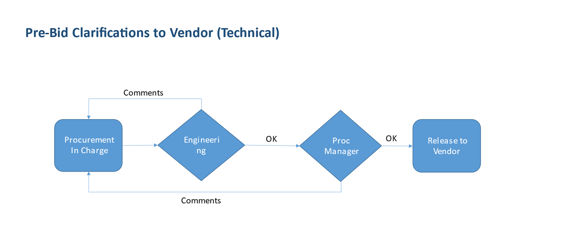

Once the RFQ is sent out to the vendors, the submission of queries by the vendors, if any, has to be addressed by the buyer in collaboration with the engineering, project control, logistic teams etc. In certain cases these queries may be clarified by the client or consultants as well. Then the submission of the bids by the vendors must be ensured by the buyer against the allocated schedule.

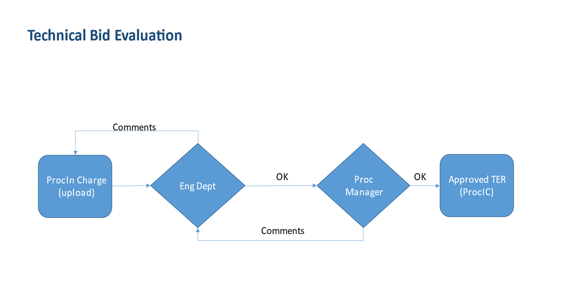

Once the bids are received, the technical part of the bid is forwarded to the engineering team for review and schedule part is reviewed by project control teams. The buyer must coordinate clarifications from engineering and project control teams and obtain the necessary clarifications as required before shortlisting the vendors for evaluation of commercial offers.

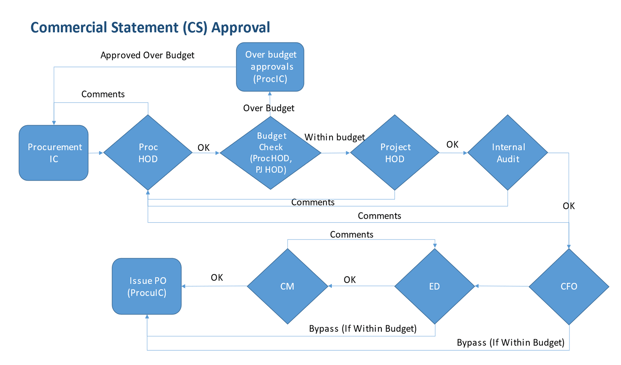

Once the commercial offers are evaluated, the buyer must obtain the approval from management to release the purchase order to the lowest bidder. In the case of the lowest bidder exceeding the budget the buyer may be asked to renegotiate the price or to look for alternate sources or ask for budget revisions.

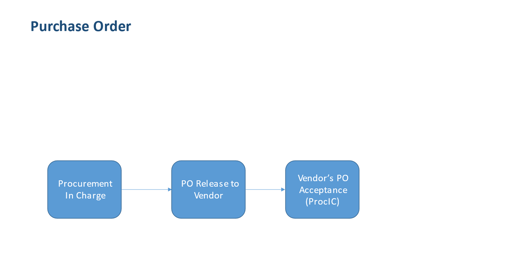

Only after all these processes are completed can the actual purchase order be issued though the ERP system.

How are all these transactions monitored by the buyer and project management team?

As you can imagine, there are multiple agencies, different types of documents, multiple revisions, clarifications, and reviews involved even before recommending for issuing a purchase order. So the question arises: are we able to track the progress of this important phase through just an ERP system or a scheduling software?

I’d say the answer is a big NO. But what is the alternative?

It’s simple. We need to track the progress of the material requisition issued until the PO is placed in a single workflow, and the progress at each stage of the workflow may be tracked through sub work flows as well. Right?

Well, this can be done by using a digital platform which can be configured to accommodate all the multistage workflows (integrated to a single flow) which will ensure minimal manual intervention while also ensuring adherence to the quality process and at the same time providing real-time status updates to the stake holders.

So to sum up, I would say that we need to use a digital platform which can do all these functions in conjunction with ERP systems and scheduling software.

To know more details, please click here

-1.png)

.jpg)